Tumble Dryer Making Noise But Not Turning? Here’s why & what to do

Tumble dryers make washdays so much easier especially during the cold, wet, winter months. When there’s a problem with the dryer, it can really cause problems.

In this article we look specifically at the causes and solutions to get a tumble dryer operational again when the drum doesn’t turn and the dryer is making a noise.

If this is the problem you’re having with your tumble dryer, keep reading.

Why Does The Tumble Dryer Make A Noise But The Drum Doesn’t Turn?

There are several reasons why the drum on a tumble dryer fails to spin which include;

| Probable Cause | Solution |

|---|---|

| Something stuck in the drum | Check the drum and remove any obstructions |

| Worn or broken drive belt | Replace drive belt |

| Drive belt off the idler pulley | Check the belt and idler pulley and replace as necessary |

| Damaged idler pulley | Replace the idler pulley |

| Worn drum roller/axle | Replace the drum roller/axle |

| Worn drum glides | Replace drum glides |

| Worn drum bearing | Replace drum bearing |

| Faulty motor | Replace the motor |

| Defective start capacitor | Replace the start capacitor |

Let’s look at each of these issues in more detail.

Check The Drum

The very first thing to check is the actual drum itself. Sometimes items can fall from pockets which can cause the drum to stop turning and cause a noise.

Items like keys, pens, pencils, bra wires, screws or nails can all cause the drum to stop spinning if they get caught between the drum and the body of the dryer.

In some cases a small coin is all it takes to prevent the drum from spinning. The coin can get wedged in between the edge of the drum and the body of the dryer.

Which is just enough to prevent the drum from rotating. You will then hear a grinding or humming noise which indicates that the motor is trying to turn but is meeting too much resistance.

Once the drum is free from obstruction again, it should work as normal.

Defective Drive Belt

The most likely reason for the drum to stop spinning is a broken or damaged drive belt. Tumble dryer drive belts are made from rubber and can stretch over time.

Once the drive belt stretches, it can easily come off the pulley and then get caught in the motor where it becomes damaged. You can check if the drive belt has broken by turning the drum by hand. If the drum turns freely and there’s no resistance at all, the belt is almost certainly broken.

Replacing a drive belt can be done by a confident DIYer but it can be a bit of a struggle stretching the new belt over the pulleys. Plus you will need to remove some panelling to access the belt, if you’re not sure you can manage this, contact a technician to do it for you.

Drive Belt Not On The Idler Pulley

The idler pulley helps in the rotation of the drum by putting tension on the drive belt. Once you have the panelling removed, you will be able to see if the drive belt is still connected to the idler pulley.

If the drive belt has come off the idler pulley, it will need to be put back on before the dryer will work again. However, you should inspect the drive belt for any wear and the idler pulley as well.

Another indicator that the problem is with the idler pulley is if you can hear a squeaking as well as the humming of the motor. This squeaking typically indicates that the bearings inside the idler pulley are worn and if this is the case, the idler pulley will need to be replaced.

Damaged Idler Pulley

As we have just seen, the idler pulley plays an important role in the rotation of the drum. If the bearings are showing any sign of wear (squeaking) the idler pulley will need to be replaced.

Worn Drum Roller/Axle

To help the drum to rotate, it has rollers, some models have 2 rollers others have 4, 2 at the front and 2 at the back. If the rollers or their axles are worn, they will not be able to assist with the turning of the drum.

If it does prove to be a worn or damaged roller and/or axle, it’s best to replace them all.

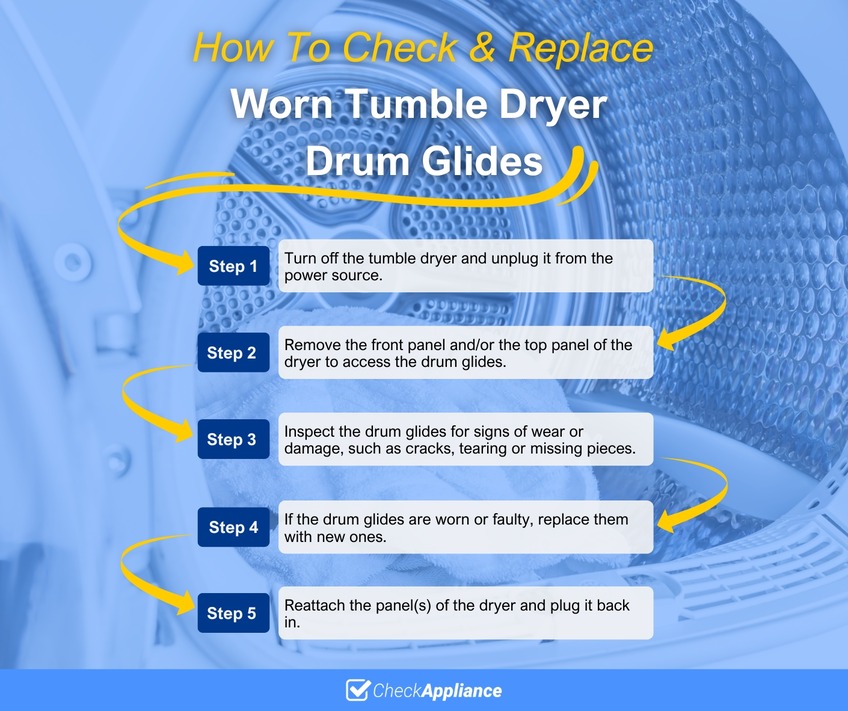

Worn Drum Glides

On some dryers, there are plastic glides or slides that help to support the front of the drum. These glides become worn over time which puts extra pressure on the motor which can sometimes cause the drum to stop spinning.

You will need to remove the front panel of the dryer to access the drum glides. If the glides prove to be worn or faulty, you should replace them.

Worn Drum Bearing

The drum is often supported by a bearing in the centre of the back of the appliance. If this bearing is worn, the drum will make a lot of noise. Plus when you remove the drive belt, the drum won’t turn.

You’ll need to remove the rear panel to access the drum bearing and if it proves to be faulty, it will need to be replaced.

Faulty Motor

The motor on a tumble dryer turns the drum and the blower wheel. The first thing to check is that the blower wheel is turning freely, if there’s nothing obstructing the blower wheel. You will need to remove the drive belt and see if the drum moves.

If the blower wheel and drum move freely, the problem is almost certainly the motor is faulty. If this is the case, the motor will need to be replaced.

Tumble dryer motors tend to be quite costly, so we would recommend getting a technician to do this job.

Defective Start Capacitor

Tumble dryer motors are induction motors and often rely on a capacitor to start. If the capacitor is faulty it can prevent the drum from spinning.

The easiest way to check if the capacitor is defective is to open the door of the dryer and spin the drum by hand. Then quickly close the door, if the drum keeps turning and then suddenly stops, it’s likely to be because the drum was about to spin in the opposite direction.

This involves restarting the motor which is why the drum has stopped. You then know that the motor is fine, it’s the capacitor that’s defective.

Please Note: Capacitors can hold a charge even once the power has been disconnected. We recommend getting a technician to check and replace a defective capacitor.

Need Tumble Dryer Repairs?

We hope this article has been helpful in solving the issue with your dryer. We have lots of other diagnostic articles for all manner of household appliances.

Feel free to use our search bar to find any other issues you might be having with an electrical appliance. Plus we also have reviews and buying guides for new appliances if your old unit has come to the end of its days and needs replacing.

SEE ALSO: Can You Put Soaking Wet Clothes In The Tumble Dryer?

Frequently Asked Questions

If your dryer is making a sound but the drum’s not spinning, it’s most likely a problem with the motor. Or it could be the drum rollers, glides, drive belt, idler pulleys, drum bearing or the capacitor.

It is not safe to run a dryer that isn’t spinning. Dryers are designed to be used when the drum is spinning as this ensures the heat is evenly distributed to each item as the drum turns. When the drum is not spinning, some items of laundry will get the full blast of that concentrated heat. This will almost certainly cause damage to those items. Plus the appliance could overheat which will cause damage to the internal components.

You can replace a dryer belt yourself but they are often a struggle as they fit on quite tightly and you’re working in an enclosed space.

A worn dryer belt creates a banging or thumping sound as it tries to turn the drum unsuccessfully.

Also, follow us on Pinterest ...